[A Course in Metallurgy, Fabio Miani, University of Udine, Italy ]

This Course on Metallurgy is basically

a compromise between the good old school of teaching Metallurgy and new

available (free for up to three components!)

software Pandat Software (http://www.computherm.com/

last release October 2014) for phase diagram calculations.

The

student will be able to have a deeper

understanding of the subject by learning to use a Calphad

based software, Pandat. Understanding of the subject will be obtained

also by using other general purpose

software like Matlab or Maple) and by solving some

the problems the textbook proposes.

Course organization

There will be less powerpoint

slides projection as generally students would expect. Learning will be based

mainly on solving specific issues, and

generalized/categorized afterwards.

Materials

It is necessary to have a computer (Windows

based or otherwise installed by virtualization) to install Pandat.

Textbook is: Modern Physical

Metallurgy, 8th edition, by Smallman and Ngan, Butterworth-Heinemann ( Elsevier) .

Additional information on Mechanical

Metallurgy could be obtained by Dieter, Mechanical Metallurgy

Prerequisites and co-requisites

The student should already possess some elementary notions of materials science and mechanical behaviour

of metals and, possibly, metallurgy. In the case of a serious lack of

this information expecially for the mechanical

behaviour of metals, he/she should consider the materials in the first parts of

the above mentioned Dieter textbook.

Course

requirements

The student will provide in due

times assignements

( by email to metallurgia16@gmail.com )related to the use of Pandat

and solutions to selected problems during the course. Partecipation is

strongly recommended. Final

exam is needed in case of uncorrect or untimely

delivery of assignments and problems. A

specific final project will be proposed during the course.

The final grade student will be based mainly ( 80%- even 90 %)

on the involvement that the student has demonstrated by working out assignements and problems during the course. In case some

recovery is needed from a mark considered low by the student, final project

work will be considered by professor up

to 20%.

Course policies

and expectations

As laptop use is necessary,

an intelligent and respectful use of contemporary devices is welcome.

Course calendar

Will

be communicated ( by email) and published at www.gotrawama.eu/metallurgia/

Readings ( and suggested links ) should

be approached briefly before classroom. Emphasis in not on memorization, but on

the ability to solve (close to real world) problems

First week

STEP 0 Purpose and aim of the course

Lesson 1: Overview of the Course - Learning needs discussion and evaluation.

Historical, Economic, and Social Perspectives of the metal related activities.

Review

of Selected Global Mineral Industries in 2011 and an Outlook to 2017

http://www.gotrawama.eu/metallurgia/globalmineralindustries.htm

Metal

prices in the United States through 2010

http://www.gotrawama.eu/metallurgia/metal%20prices

Lesson 2: Metals and

materials. What is a metal in a elementary perspective.

Mineral Facilities of Europe

http://pubs.usgs.gov/of/2010/1257/

Readings: Chapter 1: Process Metallurgy�An Argosy Through Time

http://web.a.ebscohost.com/ehost/ebookviewer/ebook/bmxlYmtfXzQ4NTE4MV9fQU41?sid=85dc640b-a9f0-4446-9329-ccdb298881be@sessionmgr4001&vid=0&format=EB&lpid=lp_15&rid=0

Metal extraction procedures

from an elementary perspective.

Readings: Chapter 1.1: Introduction to Metallurgical

Processing

http://web.a.ebscohost.com/ehost/ebookviewer/ebook/bmxlYmtfXzQ4NTE4MV9fQU41?sid=85dc640b-a9f0-4446-9329-ccdb298881be@sessionmgr4001&vid=0&format=EB&lpid=lp_15&rid=0#

Metal oxydes

and metal recycling: a way to a greener production.

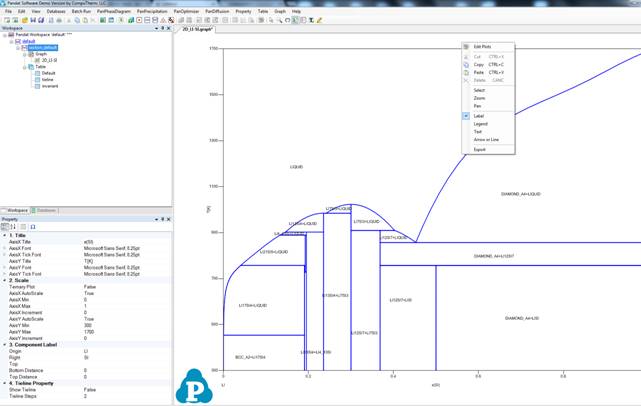

Lesson 3: Pandat software

and metallurgical thermochemistry

Using Pandat Basics: http://www.computherm.com/

Use of Pandat for the Li.Si phase diagram: paper from Maria Helena Braga, Oporto,

Portugal - http://paginas.fe.up.pt/~mbraga/the_group.html

Elements (2)

|

Name |

Structure |

Atomic

Number |

Atomic

Weight |

H298 |

S298 |

|

LI |

BCC_A2 |

3 |

6.941 |

4623.3 |

29.095 |

|

SI |

DIAMOND_A4 |

14 |

28.085 |

3217.5 |

18.82 |

Phases (10)

|

Name |

Model |

Type_Def Code |

Lattice

Size |

Constituent |

|

BCC_A2 |

CEF (SLN) |

|

(1)(3) |

(LI,SI)(VA) |

|

DIAMOND_A4 |

CEF (SLN) |

|

(1) |

(LI,SI) |

|

LI12SI7 |

CEF (ST2) |

|

(0.6316)(0.3684) |

(LI)(SI) |

|

LI13SI4 |

CEF (ST2) |

|

(0.7647)(0.2353) |

(LI)(SI) |

|

LI17SI4 |

CEF (ST2) |

|

(0.8095)(0.1905) |

(LI)(SI) |

|

LI21SI5 |

CEF (ST2) |

|

(0.80769)(0.19231) |

(LI)(SI) |

|

LI4_13SI |

CEF (ST2) |

|

(0.80488)(0.19512) |

(LI)(SI) |

|

LI7SI3 |

CEF (ST2) |

|

(0.7)(0.3) |

(LI)(SI) |

|

LIQUID |

CEF (SLN) |

|

(1) |

(LI,SI) |

|

LISI |

CEF (ST2) |

|

(0.5)(0.5) |

(LI)(SI) |

Phase Parameters

|

Name |

Property |

x-Term |

x-order |

Parameter |

T-limit

(K) |

|

BCC_A2 |

L0 |

(LI)(VA) |

0 |

+GHSERLI |

6000 |

|

L0 |

(SI)(VA) |

0 |

+30225.0-9.59*T+GHSERSI |

6000 |

|

|

L |

(LI,SI)(VA) |

0 |

+0 |

6000 |

|

|

DIAMOND_A4 |

L0 |

(LI) |

0 |

+26963.2+15.83*T+GHSERLI |

6000 |

|

L0 |

(SI) |

0 |

+GHSERSI |

6000 |

|

|

L |

(LI,SI) |

0 |

+0 |

6000 |

|

|

LI12SI7 |

L0 |

(LI)(SI) |

0 |

-24817+2.49*T

+0.6316*GHSERLI+0.3684*GHSERSI |

6000 |

|

LI13SI4 |

L0 |

(LI)(SI) |

0 |

-25207+4.15*T

+0.7647*GHSERLI+0.2353*GHSERSI |

6000 |

|

LI17SI4 |

L0 |

(LI)(SI) |

0 |

-22818+4.997*T

+0.8095*GHSERLI+0.1905*GHSERSI |

6000 |

|

LI21SI5 |

L0 |

(LI)(SI) |

0 |

-22683+4.608*T

+0.80769*GHSERLI+0.19231*GHSERSI |

6000 |

|

LI4_13SI |

L0 |

(LI)(SI) |

0 |

-23045.5+4.79*T

+0.80488*GHSERLI+0.19512*GHSERSI |

6000 |

|

LI7SI3 |

L0 |

(LI)(SI) |

0 |

-26700+3.11*T

+0.700*GHSERLI+0.300*GHSERSI |

6000 |

|

LIQUID |

L0 |

(LI) |

0 |

-7883.612+211.841861*T

-38.940488*T*LN(T)+.035466931*T**2 -1.9869816E-05*T**3+159994*T**(-1) |

250 |

|

+12015.027-362.187078*T+61.6104424*T*LN(T)-.182426463*T**2

+6.3955671E-05*T**3-559968*T**(-1) |

453.6 |

||||

|

-6057.31+172.652183*T-31.2283718*T*LN(T)+.002633221*T**2

-4.38058E-07*T**3 -102387*T**(-1) |

3000 |

||||

|

L0 |

(SI) |

0 |

+50696.4-30.0994*T

+2.09307E-21*T**7+GHSERSI |

1687 |

|

|

+49828.2-29.5591*T+4.20369E+30*T**(-9)+GHSERSI |

6000 |

||||

|

L |

(LI,SI) |

0 |

-115035+23*T |

6000 |

|

|

L |

(LI,SI) |

1 |

-55980+17*T |

6000 |

|

|

L |

(LI,SI) |

2 |

+9764 |

6000 |

|

|

L |

(LI,SI) |

3 |

+35653 |

6000 |

|

|

LISI |

L0 |

(LI)(SI) |

0 |

-19789+2.1599*T

+0.5*GHSERLI+0.5*GHSERSI |

6000 |

Functions

|

Name |

Expression |

T-limit

(K) |

|

GBCCSI |

+30225.0-9.59*T+GHSERSI |

6000 |

|

GHSERLI |

-10583.817+217.637482*T-38.940488*T*LN(T)

+.035466931*T**2-1.9869816E-05*T**3+159994*T**(-1) |

453.6 |

|

-559579.123+10547.8799*T-1702.88865*T*LN(T)+2.25832944*T**2

-5.71066077E-04*T**3+33885874*T**(-1) |

500 |

|

|

-9062.994+179.278285*T-31.2283718*T*LN(T)+.002633221*T**2

-4.38058E-07*T**3-102387*T**(-1) |

3000 |

|

|

GHSERSI |

-8162.609+137.236859*T-22.8317533*T*LN(T)

-1.912904E-3*T**2-0.003552E-6*T**3+176667*T**(-1) |

1687 |

|

-9457.642+167.281367*T-27.196*T*LN(T)

-420.369E28*T**(-9) |

3600 |

|

|

UN_ASS |

0 |

300 |

http://www.gotrawama.eu/metallurgia/LiSi.htm

Li-Si Phase Diagram from the

Paper

Li-Si Phalse Diagram using only SGTE (pure

metals) data

Possible Digression on

Alkali Metals: https://en.wikipedia.org/wiki/Alkali_metal

Possible readings: 1

Atoms and Atomic Arrangements http://web.b.ebscohost.com/ehost/ebookviewer/ebook/bmxlYmtfXzQ4NjI4NF9fQU41?sid=6ad42165-2929-43aa-9ba9-095878d321c1@sessionmgr112&vid=0&format=EB&lpid=lp_1&rid=0#

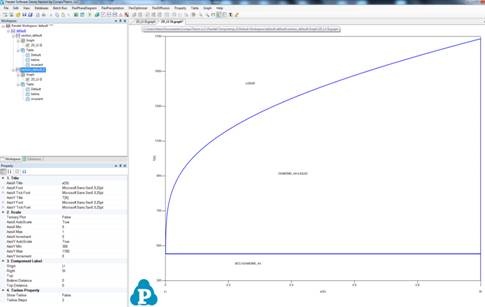

(Second Week) Lesson 4: Another Pandat Simulation of Li-Sn

phase diagram.

http://www.gotrawama.eu/metallurgia/LiSn.htm

Elements (2)

|

Name |

Structure |

Atomic

Number |

Atomic

Weight |

H298 |

S298 |

|

LI |

BCC_A2 |

3 |

6.941 |

4623.3 |

29.095 |

|

SN |

BCT_A5 |

50 |

118.71 |

6322 |

51.195 |

Species (1)

|

Name |

Formula |

Charge |

|

LI4SN |

(LI)4(SN)1 |

0 |

Type

Definition (1)

|

Type

Code |

Function |

Phase |

Property |

Parameter |

|

& |

AMEND_PHASE_DESCRIPTION |

BCC_A2 |

MAGNETIC |

(-1) (0.4) |

Phases (4)

|

Name |

Model |

Type_Def Code |

Lattice

Size |

Constituent |

|

BCC_A2 |

CEF (SLN) |

& |

(1)(3) |

(LI,SN)(VA) |

|

BCT_A5 |

CEF (ST1) |

|

(1) |

(SN) |

|

DIAMOND_A4 |

CEF (ST1) |

|

(1) |

(SN) |

|

LIQUID |

CEF (SLN) |

|

(1) |

(LI,LI4SN,SN) |

Phase Parameters

|

Name |

Property |

x-Term |

x-order |

Parameter |

T-limit

(K) |

|

BCC_A2 |

L0 |

(LI)(VA) |

0 |

+GHSERLI |

3000 |

|

L0 |

(SN)(VA) |

0 |

+GBCCSN |

3000 |

|

|

BCT_A5 |

L0 |

(SN) |

0 |

+GHSERSN |

3000 |

|

DIAMOND_A4 |

L0 |

(SN) |

0 |

-9579.608+114.007785*T

-22.972*T*LN(T)-.00813975*T**2+2.7288E-06*T**3+25615*T**(-1) |

298.15 |

|

-9063.001+104.84654*T-21.5750771*T*LN(T)-.008575282*T**2

+1.784447E-06*T**3-2544*T**(-1) |

800 |

||||

|

-10909.353+147.396537*T-28.4512*T*LN(T) |

3000 |

||||

|

LIQUID |

L0 |

(LI) |

0 |

+GLIQLI |

3000 |

|

L0 |

(LI4SN) |

0 |

-205264.343+187.457195*T

-16.7055876*T*LN(T)+4*GLIQLI+GLIQSN |

3000 |

|

|

L0 |

(SN) |

0 |

+GLIQSN |

3000 |

|

|

L |

(LI,SN) |

0 |

-64124.4038-15.9626763*T

+2.04164413*T*LN(T) |

3000 |

|

|

L |

(LI,LI4SN) |

0 |

30074.1641-19.0031351*T

-1.46094182*T*LN(T) |

3000 |

|

|

L |

(LI4SN,SN) |

0 |

-24652.1452-259.57801*T

+28.4690441*T*LN(T) |

3000 |

Functions

|

Name |

Expression |

T-limit

(K) |

|

GBCCSN |

+GHSERSN+4400-6*T |

3000 |

|

GFCCLI |

+GHSERLI-108+1.3*T |

3000 |

|

GFCCSN |

+GHSERSN+5510-8.46*T |

3000 |

|

GHCPLI |

+GHSERLI-154+2*T |

3000 |

|

GHCPSN |

+GHSERSN+3900-7.646*T |

3000 |

|

GHSERLI |

-10583.817+217.637482*T-38.940488*T*LN(T)

+.035466931*T**2-1.9869816E-05*T**3+159994*T**(-1) |

453.6 |

|

-559579.123+10547.8799*T-1702.88865*T*LN(T)+2.25832944*T**2

-5.71066077E-04*T**3+33885874*T**(-1) |

500 |

|

|

-9062.994+179.278285*T-31.2283718*T*LN(T)+.002633221*T**2

-4.38058E-07*T**3-102387*T**(-1) |

3000 |

|

|

GHSERSN |

-7958.517+122.765451*T-25.858*T*LN(T)

+5.1185E-04*T**2-3.192767E-06*T**3+18440*T**(-1) |

250 |

|

-5855.135+65.443315*T-15.961*T*LN(T)-.0188702*T**2+3.121167E-06*T**3

-61960*T**(-1) |

505.08 |

|

|

+2524.724+4.005269*T-8.2590486*T*LN(T)-.016814429*T**2

+2.623131E-06*T**3-1081244*T**(-1)-1.2307E+25*T**(-9) |

800 |

|

|

-8256.959+138.99688*T-28.4512*T*LN(T)-1.2307E+25*T**(-9) |

3000 |

|

|

GLIQLI |

-7883.612+211.841861*T-38.940488*T*LN(T)

+.035466931*T**2-1.9869816E-05*T**3+159994*T**(-1) |

250 |

|

+12015.027-362.187078*T+61.6104424*T*LN(T)-.182426463*T**2

+6.3955671E-05*T**3-559968*T**(-1) |

453.6 |

|

|

-6057.31+172.652183*T-31.2283718*T*LN(T)+.002633221*T**2

-4.38058E-07*T**3-102387*T**(-1) |

3000 |

|

|

GLIQSN |

+GHSERSN+7103.092-14.087767*T

+1.47031E-18*T**7 |

505.08 |

|

+9496.31-9.809114*T-8.2590486*T*LN(T)-.016814429*T**2

+2.623131E-06*T**3-1081244*T**(-1) |

800 |

|

|

-1285.372+125.182498*T-28.4512*T*LN(T) |

3000 |

|

|

UN_ASS |

0.0 |

300 |

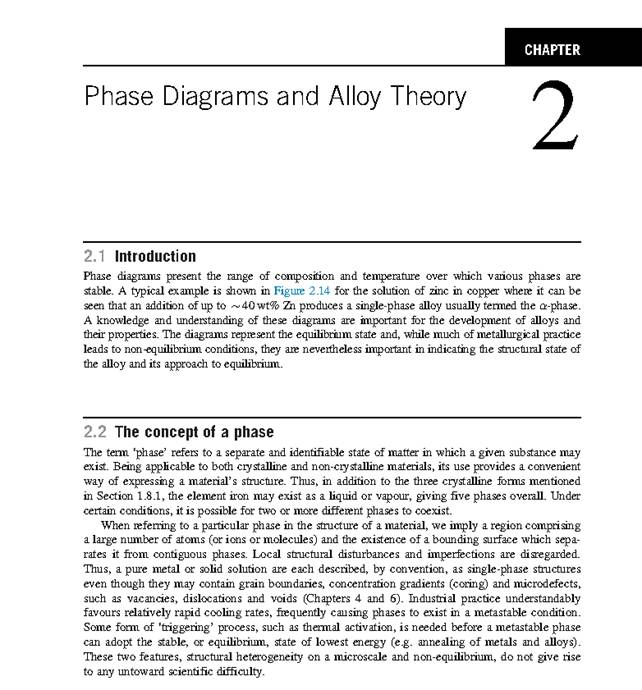

Readings:The good old school.. Phase

Diagrams and alloy Theory

Li-Sn

Phase Diagram

Digression: Various

Activities of Prof. Sadoway at MIT Digression: Is

This Ambri’s

New Liquid-Metal Battery Materials Formula?

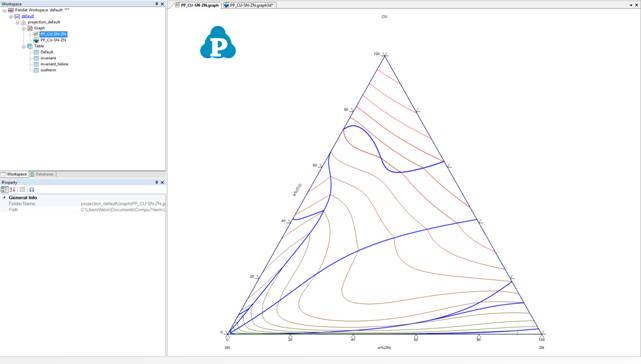

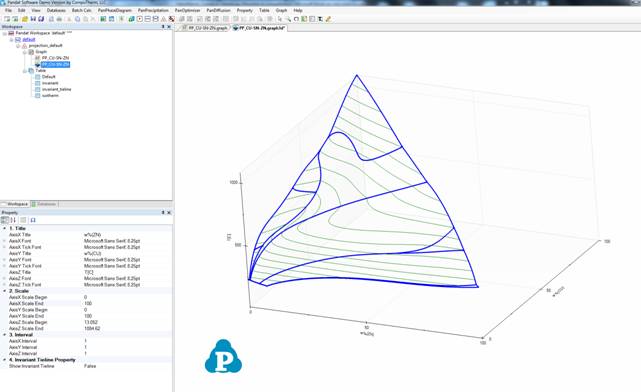

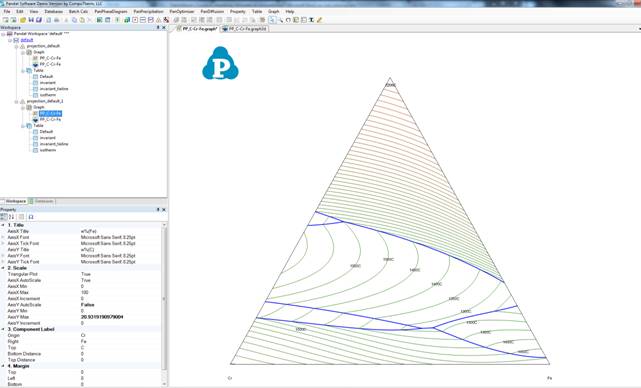

Lesson 5: A more complicated

situation, a ternary phase diagram. The case of Cu Sn

Zn.

http://www.sciencedirect.com/science/article/pii/S0925838808019816

Liquidus projection Cu-Sn-Zn

and Liquidus

Surface

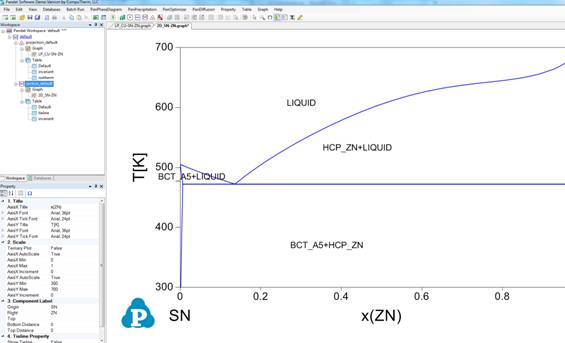

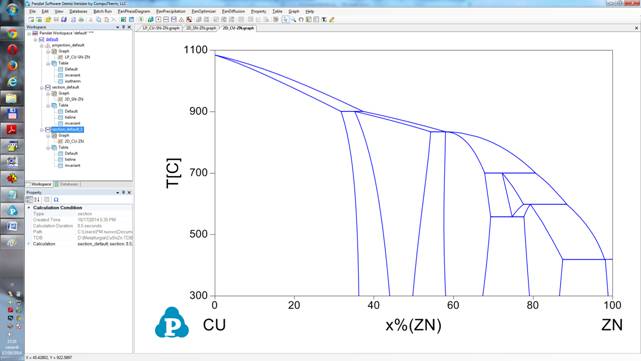

Lesson 6: It seems easier: the case of Sn-Zn, Cu-Zn

phase diagrams

|

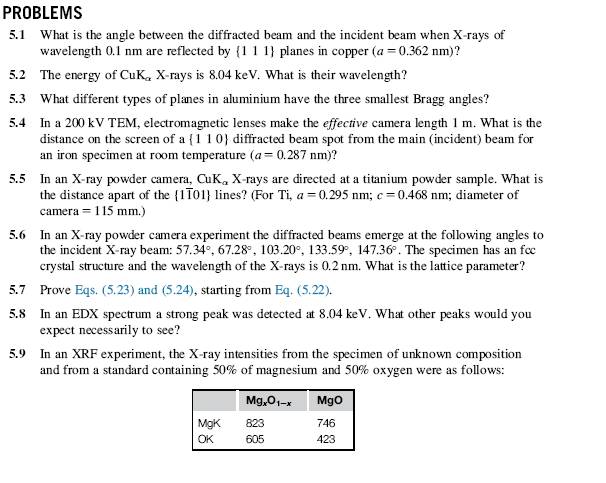

Readings: Chapter 5

Characterization and Analysis. Problems Chapter 5. |

|

|

|

|

Lesson

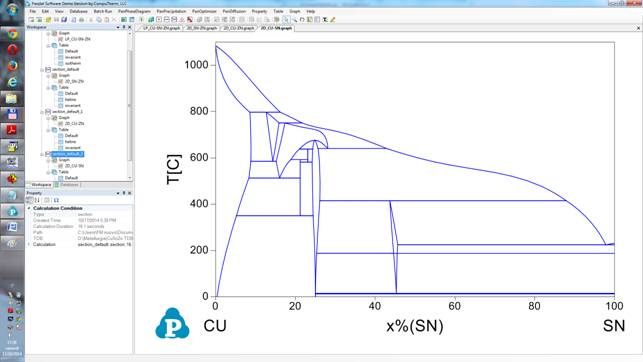

7: The case of Cu-Sn. Copper alloys: brasses bronzes

and much more

Lesson 8: More and more

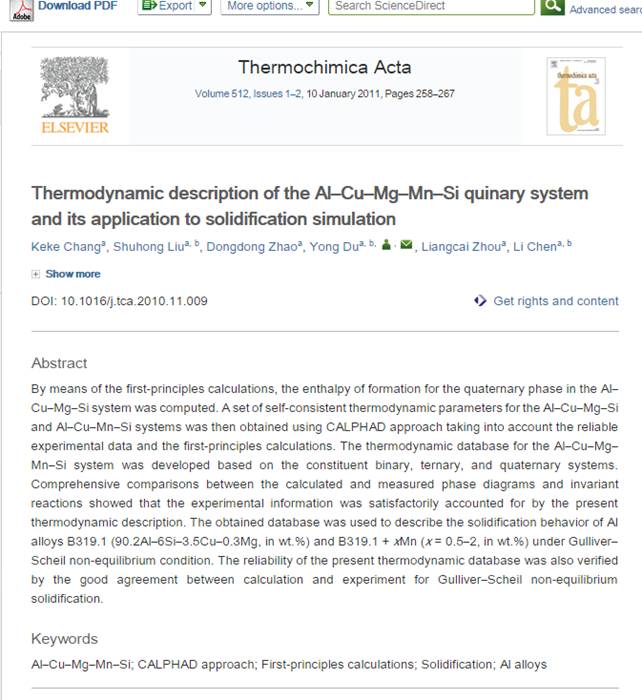

difficult - the quaternary Al-Cu-Si-Mg and quinary Al-Cu-Si-Mg-Mn . Checking the open data that we have.. with binaries and ternaries with the “professional” version

of Pandat (8.2)

http://www.sciencedirect.com/science/article/pii/S0040603110003990

Lesson 9: Al-Cu-Si ternary. Aluminum alloys

http://www.sciencedirect.com/science/article/pii/S092583881101913X

Lesson 10: Physical

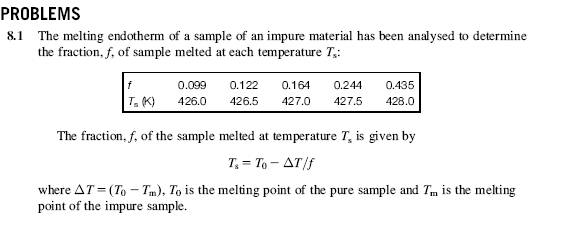

Properties Readings: Chapter 8 Problems Chapter 8

|

|

|

|

Work of Gancarz based on Henein-Roach viscosimeter

Lesson

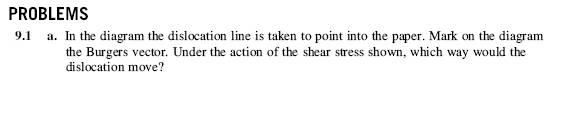

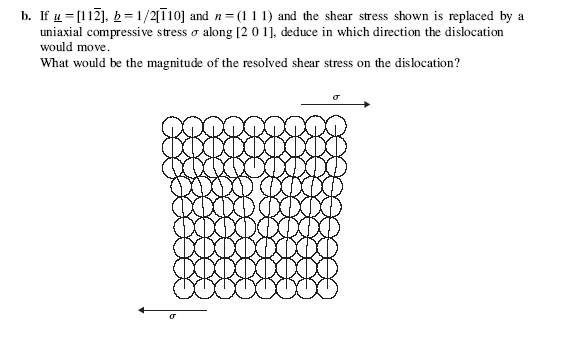

11 : Plastic Deformation and Dislocation Behaviour Reading: Chapter 9 Problems

Chapter 9

|

|

|

|

Additional Readings: Dieter

Mechanical Metallurgy

https://archive.org/stream/mechanicalmetall00diet#page/n5/mode/2up

https://archive.org/stream/mechanicalmetall00diet#page/n25/mode/2up

“.. for students of

engineering who have had an advanced course on strength of materials or machine

design, it probably will be possible to skim rapidly over these chapters..”

Readings: Learning Dieter

Dislocation Theory.. Not the easiest thing to do!!

https://archive.org/stream/mechanicalmetall00diet#page/158/mode/2up

Lesson 12 : Surfaces, Grain

Boundaries and Interfaces Reading: Chapter 10 Problems Chapter 10

Lesson 13 : Work hardening

and annealing : Chapter 11 Problems Chapter 11

Lesson 14 : Did we forget about something? Reading: Chapter 14 Selected Alloys

Problems Chapter 14

The textbook reports on

steels, cast irons, superalloys, titanium alloys,

structural intermetallic compounds, aluminium alloys,

copper and copper alloys.. I would add magnesium alloys.. the Science Direct (Elsevier) journal of

magnesium and alloys is open access!! http://www.sciencedirect.com/science/journal/22139567

The textbook reports on steels, cast irons,superalloys, titanium alloys, copper and copper alloys.. I would add magnesium alloys..

The Science Direct (Elsevier) journal of magnesium and alloys is open access!!

Technical and Commercial Information on Copper and Copper Alloys

Lesson 15: Phase Diagrams back! Fe-Cu-C, Fe-Cr-C, Fe-Cr-Ni phase diagrams. Yes,

there is also a Fe-C diagram..

Pandat Liquidus

Surface Fe-Cr-C

See also.. Madeleine Durand-Charre. The Microstructure of Steels and Cast Irons https://www.academia.edu/7563031/MADELEINE_DURAND-CHARRE._THE_MICROSTRUCTURE_OF_STEELS_AND_CAST_IRONS

Lesson 16 : Continuation of

15 and .. A world of steel: WorldSteel site

http://www.worldsteel.org Steeluniversity http://www.steeluniversity.org

Lesson 17/18/ Steel transformations

Chapter 12 Problems Chapter 12

Lesson 19 : Scientific and Technical aspects of steels. The case of steels for

bearings

After.. Prof. H.D.K. Bhadeshia, Cambridge ( and SKF University Technology Center for Steels http://www.msm.cam.ac.uk/phase-trans/2011/Bearings/)

And Ovako:

http://www.ovako.com/Global/Downloads/Product_information/Ovako_Group/EN/Steels%20for%20Bearings%20from%20Ovako.pdf

Lesson 20: - ideas and examples from Materials Science of Steel www.gotrawama.eu/Metallurgiaacciaio/ to develop final project